- Home

- Chemical Vapor Deposition Industry

Chemical Vapor Deposition Industry

Custom Solutions for the Chemical Vapor Deposition (CVD) Industry

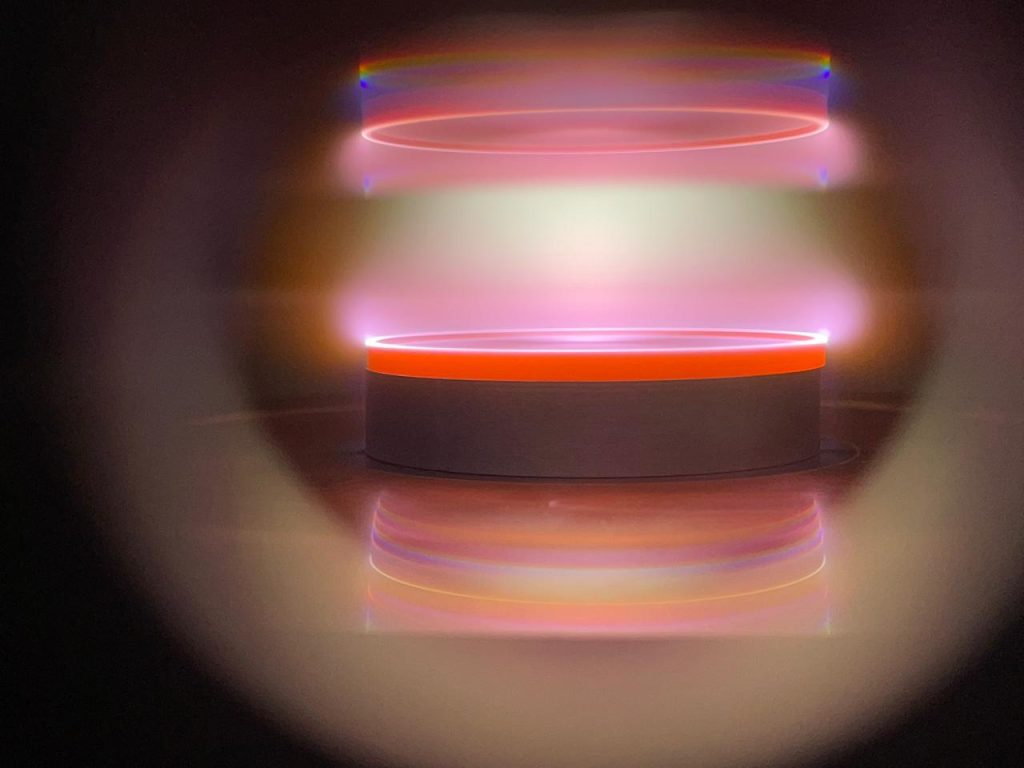

Velfab Engineers is a trusted partner for the Chemical Vapor Deposition industry, delivering precision-engineered vacuum chambers and complete CVD systems that meet the high-purity and high-performance requirements of chemical vapor deposition processes. Our product range includes custom-designed vacuum chambers, gas delivery systems, and advanced vacuum and microwave sealing solutions, crafted to support the uniformity and stability essential for CVD applications. With expertise in materials like Aluminium, Stainless Steel, Molybdenum, Copper and Inconel, and other vacuum-compatible alloys, Velfab ensures each component performs reliably under the demanding conditions of CVD operations.Guaranteeing uniform deposition and process consistency. Be it 10 systems, 50 systems or 1000 systems, we guarantee consistency in performance and results across entire installations in your lab.Industry-Specific Applications and BenefitsOur solutions for the CVD industry are tailored to enhance efficiency, control, and consistency in deposition processes, supporting both research and large-scale manufacturing applications. Velfab’s expertise spans the following key applications in CVD: Custom Vacuum ChambersVelfab Engineers specializes in manufacturing custom-designed vacuum chambers for CVD, built to provide a stable, high-purity environment essential for precise film deposition. These chambers, crafted from premium aluminium alloys, high-purity stainless steel, other customer specific materials ensuring superior vacuum and microwave sealings, maintaining ultra-clean conditions necessary for high-quality coating and uniform deposition across substrates.

- Gas Delivery and Flow Control Systems Precise gas delivery is vital for consistent and controlled deposition in CVD processes. Velfab produces high-precision gas manifolds and flow control systems that ensure reliable and contamination-free gas flow. Our components are made from high purity materials, designed to handle reactive gases safely and maintain stability throughout the deposition process.

- Heating and Temperature Management Components Temperature control is critical to achieving uniform deposition in CVD. Velfab offers custom thermal distribution systems, and cooling plates that help maintain consistent and optimal temperature throughout the process. Engineered for superior heat distribution, our temperature management components ensure uniformity and reduce process variability.

- Sealing and Containment Solutions High-quality sealing solutions are essential to maintaining vacuum integrity in CVD applications. Velfab provides precision bellow-sealed assemblies, vacuum fittings, and adapters designed to secure UHV containment and prevent contamination. These components enhance system reliability, contributing to consistent deposition results and prolonged equipment life.

- • Drilling/Frac Applications In drilling and hydraulic fracturing (frac) operations, components face intense pressure, wear, and abrasive conditions. Velfab Engineers produces high-strength components such as drill bits, collars, stabilizers, and frac pump components designed to withstand these extreme conditions. Utilizing durable materials like Inconel and super duplex stainless steel, our parts support prolonged operational life and efficiency, allowing for reduced downtime and improved productivity in drilling and fracturing processes.

- Advanced Technology

- Inaccurate Inventory

Industries we Serve

Contact us

Have questions?

Frequently Asked Questions

What services does Velfab offer to the CVD industry?

Velfab delivers custom vacuum chambers, gas delivery systems, sealing solutions, and complete CVD systems.

What materials are used in your vacuum chambers and CVD systems?

Velfab uses aluminum, stainless steel, molybdenum, copper, Inconel, and other vacuum-compatible alloys.

How does Velfab support temperature management in CVD systems?

They offer thermal distribution systems and cooling plates engineered to maintain uniform temperature during deposition.

Are your vacuum chambers compatible with microwave sealing?

Yes, Velfab designs chambers with microwave-compatible sealing for advanced CVD applications.

If you have any questions let us know

Do you have any questions? Write and our specialists will answer you.