Designing machined components is a balancing act between functionality, cost, and manufacturability. Even small design oversights can lead to higher production costs, extended lead times, or even manufacturing failures. At Velfab, we emphasize the importance of DFM (Design for Manufacturability) in machining to help our clients create parts that are efficient, cost-effective, and easy to […]

When it comes to industrial applications, choosing the right stainless steel grade is more than just picking a metal—it’s about ensuring durability, efficiency, and long-term performance. With so many stainless steel grades available, it can be overwhelming to determine which one is best suited for your needs. Whether you’re in manufacturing, construction, or engineering, selecting […]

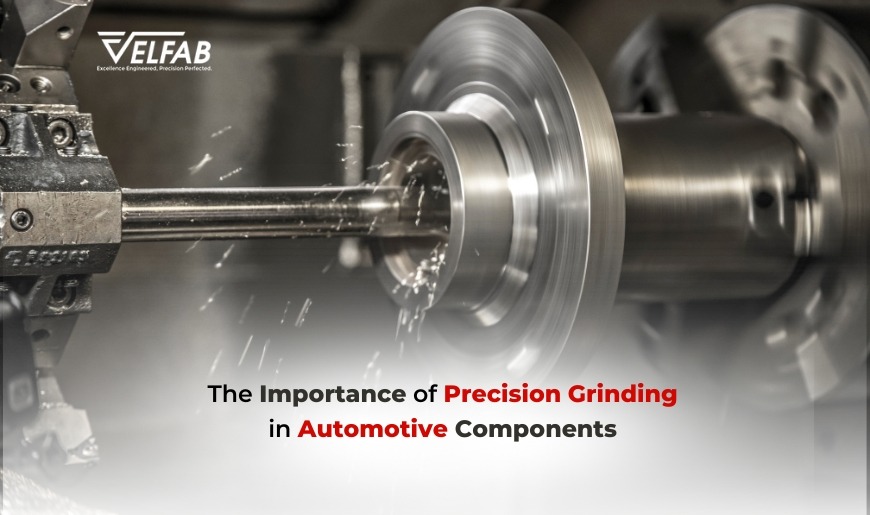

In the realm of automotive manufacturing, achieving unparalleled precision and performance is paramount. One critical process that ensures these standards is precision grinding. This meticulous machining technique is instrumental in producing automotive components that meet exacting specifications, thereby enhancing vehicle reliability and efficiency. Understanding Precision Grinding Precision grinding is a machining process that involves the […]

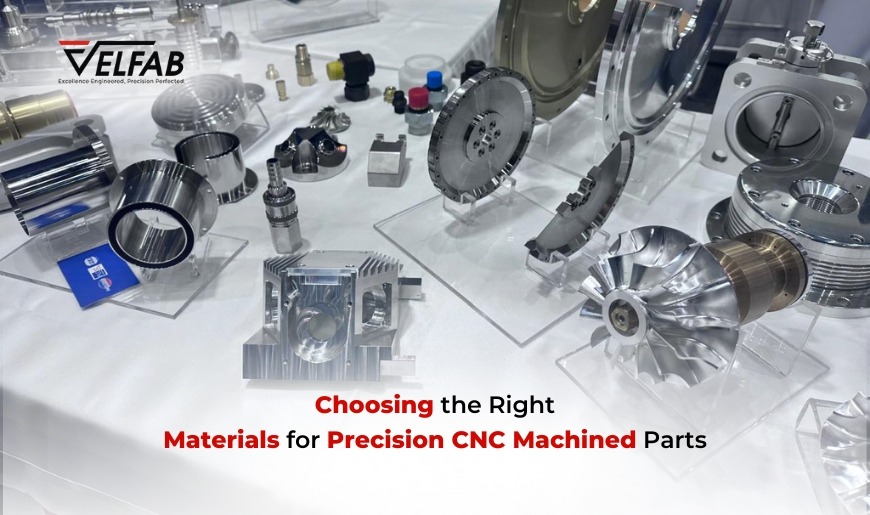

Choosing the appropriate materials for precision CNC machined parts is crucial to ensure optimal performance, durability, and cost-effectiveness. The material selection impacts not only the functionality of the component but also the efficiency of the machining process itself. In this guide, we will explore key considerations to help you make informed decisions when selecting materials […]

In the world of large-scale manufacturing, time is money. Every minute saved, every step streamlined, and every cost reduced adds up to big wins. So, it’s no surprise that manufacturers are constantly on the lookout for smarter ways to get the job done faster, cheaper, and better. One of the unsung heroes of this push […]

- 1

- 2